The AAI ACR (originally designated as the AAI AIWS) was a prototype assault rifle developed for the Advanced Combat Rifle program.

In Phase III of the program, it was one of the top four prototypes, alongside the Heckler & Koch ACR, Steyr ACR, and Colt ACR, while two other prototypes were dropped earlier on in the program before reaching Phase III. Ultimately, none of them proved to have 100% improved performance over the M16A2.

One unit is on exhibit with the other three ACR Phase III prototypes at the National Infantry Museum in Fort Benning, Georgia. Another unit, serial number #001, is in the collection of the Behring Center National Museum of American History[1].

Design Details[]

It has a long profile, which aids the shooter in point-fire situations.

The ACR is gas-operated and used a three-chambered breech system which moved very quickly in and out of engagement with the barrel to allow for very fast cycling (1,800 to 2,000 rounds per minute) of a three-round burst. It was capable of open or closed bolt operation depending on the firing mode. The original 1989 prototypes were capable of fully automatic fire at a cyclic rate of 600 rounds per minute, but the later 1990 prototypes did not have this. The earlier AIWS caseless ammo firing versions had a strip of copper added to the bolt's length and refractory metal on the bolt face to combat cook-off and erosion. To further combat cook-off, the chamber was wrapped up inside an aluminum block heat sink. Heat would transfer from the chamber wall into the aluminum heat sink.

The weapon's muzzle carries a rather unusual compensator/muzzle brake system which, in the case of the 1990 prototypes, has been especially designed to work with the flechettes, along with reducing the muzzle blast and noise level. The barrel is rifled with very slow twist - one turn in 85 inches - which gives a fired flechette a degree of roll stabilization and helps with accuracy.

As standard, the ACR had traditional iron sights, but the weapon can be configured with a quick-release, 4x ACOG optic scope for longer ranged engagements. The original 1989 prototypes used a custom-designed optical sight by AAI, which features a windage knob, two super elevation knobs (one of which for the rear peep sight), a unity power sight, a tritium illumination source, and a 3x telescope. This sight can be configured for ranges from 300 to 600 meters.

A version of the 1989 prototype with a bullpup configuration was planned, but it was never realized.

Ammunition[]

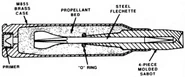

Originally, the weapon used 5.56×25mm caseless ammunition developed by Hercules Inc. made out of standard nitrocellulose propellant compressed with an acetonei/collodion binder. It used two different types of projectiles; a 5.56mm heavy bullet, and a 4.32mm steel penetrator in a four-part sabot. Rounds are fed into the weapon via a straight 36-round two-row box magazine or a 50-round drum. Benefits from the caseless ammunition included an increase in combat load at up to 50% cost reduction, elimination of the case extraction and ejection cycles, and reductions in loaded weight for the rifle. The 36-round magazine is factory-sealed with a cap, which is broken when it is inserted into the weapon.

The later 1990 prototype, like its design predecessors in the form of the AAI SPIW, XM19, XM70, and SBR, fired fin-stabilized flechettes. The ammunition used the same casing as with the standard 5.56×45mm NATO round, but with the addition of using a 10.2 grain (.660 grams), 1.6×41.27mm steel flechette encased in a four-part sabot. Compared to standard bullets, the flechettes had much lower recoil and a flatter trajectory. They are loaded into the weapon via a forward-curved 30-round box magazine. One variation of the ammunition used the .222 Remington Magnum as its parent case.

The flechette idea is not new, as several manufacturers, including AAI, had experimented with flechettes as rifle projectiles as far back as during the 1960s. At that time, however, the materials and construction of the flechette cartridge were not particularly good. By modern standards, new materials and improved technology has made the flechette concept more acceptable, and the ACR was considered a good design, although not sufficiently accurate for the purpose intended.

Drawbacks[]

The major drawback of the AAI prototype was that it could not use standard 5.56×45mm NATO rounds, despite its ammunition using a similar or the exact same casing. Because of the mechanism, it is dangerous to fire standard rounds from the gun. As a consequence, they had made the magazine proprietary to the weapon so that the user could avoid loading the incorrect kind of ammo into it, though a standard round can be loaded into the weapon manually by hand.

The AAI AIWS prototypes had fragile propellant bodies for the caseless rounds as AAI had hired Hercules Inc. to make the ammunition, but the industry had not been involved in such fabrication methods for a long time and the knowledge to make stronger propellant bodies had been lost in the American industry over time. The AIWS prototypes had also had no means to extract a broken round. This would result in stoppage happening often enough that it interfered with cook-off tests. The highest they got to fire in a cook-off test before stoppage was 75 rounds. In one test however there was a fire severe enough that the gun did not stop firing till all rounds were fired. While AAI's heat sink worked, the propellant was still very much inferior to the H&K G11's caseless ammunition.

AAI was convinced that they could solve this problem with better packaging technology to prevent and retard sympathetic ignition, but they had run out of funding. Ironically, it was noted by U.S. Army personnel that the simplified mechanics, such as the heat sink of the AAI AIWS caseless prototype, could have been combined with the more durable high-ignition temperature propellant of the H&K G11's ammunition and result in a weapon superior to both and less complex than the G11. Due to protection under license agreements the details on Heckler & Koch/Dynamit Nobel's superior propellant could not be divulged. The final irony was the U.S. Army itself could not test combining the two technologies together in-house due to lack of funding.

Gallery[]

See also[]

- ACR program entrants

- AAI ACR design predecessors

- Also see

- Advanced Combat Rifle program

- Caseless ammunition

- Flechette

- 5.56×25mm AAI AIWS

- 5.56×45mm Flechette

- 5.56×47mm Flechette