The Heckler & Koch G11 is a prototype assault rifle made by Heckler and Koch. It was developed during the Cold War to replace the G3 battle rifle in West German service; this never came to fruition. It uses caseless ammunition which is a rarity among firearms.

The G11 project involved a series of weapons under the same family: a rifle (G11), a carbine (G11 K2), an LMG (LMG11), a PDW (NBW) and an unnamed SMG. The G11 would be one of six prototype guns to enter the Advanced Combat Rifle program and be one of the four finalists.

Although the weapon was a technical success, it never entered full production due to the political changes of German reunification and lack of a procurement contract.[1]

History

The G11 project was first created by Mauser GmbH in the 1960s. The Mauser G11 fired 4.75×21mm caliber caseless rounds from an internal 10-round helical magazine. It was trialed and rejected by NATO, but the project was overtaken by Heckler and Koch shortly afterward.

Another entrant made by Industriewerke Karlsruhe (IWK) developed in the early 1970s had 3 vertical staggered barrels. Simplicity of the IWK G11 was ensured by the fact it used interchangeable revolving 51-round drum magazines. Such a system, in addition to ease power supply circuit, high stability and provide ammunition to both mechanical stress and overheating when shooting, in fact the rifle was chambered in so much as there were leftover rounds in the magazine. The price paid for this simplification, is that the weapon was too heavy, and the dimensions of the drum magazines, as well as the three barrels and the impossibility of automatic fire found in assault rifles, the IWK G11 rifle shot either single shots or volleys in three instant shots.

The Heckler and Koch G11 was originally slated to replace the aging G3 rifle. Designed by Gesellschaft für Hülsenlose Gewehrsysteme, also known as GSHG, a conglomerate of companies consisting of Heckler & Koch, Dynamit Nobel and Hensoldt Wetzlar, initial production of the G11 began in the 1970s and field testing began in the 1980s. In March 1987, after 14 different prototypes, the G11 (later re-designated as the G11 K1) entered trial production. The design was modified further, and in 1988, the G11 K2 carbine was developed and introduced. Tests in 1989 proved that the G11 K2 boasted 50% improved accuracy over the G3.

By 1991/2, the project was completed and was adopted by the Bundeswehr with an order for 300,000 rifles placed for the period between 1990-2002. However, with the reunification of Germany the project stumbled as it became clear the budget would not exist for even the original order, nevermind the additional G11s required to replace the Soviet-issue rifles of the 108,000-strong East German Landstreitkräfte of the Nationale Volksarmee. The rifle was struck from the procurement list in 1992 and by 1993 had been totally cancelled, in part because it could not be modified to fire the NATO-standard 5.56mm round. Instead of the G11, the G3 was replaced by a more conventional rifle, the Heckler & Koch G36.

A variation of the G11 resembling the G11 K1 was entered in the Advanced Combat Rifle program held in the United States of America, along with five other contestants in the 1980s, with the winner of the program replacing the M16A2. However, none of the four finalists were deemed "good enough". The U.S. Army was looking for 100% improvement in first-hit probability over the M16A2, which was perhaps too lofty a goal for such a program.

There were a total of 266 G11 weapons produced (numbered 0 through 265), all of which being prototypes and testing devices.

Design Details

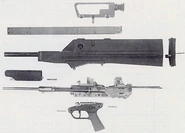

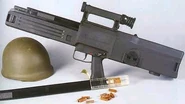

G11 K2 carbine

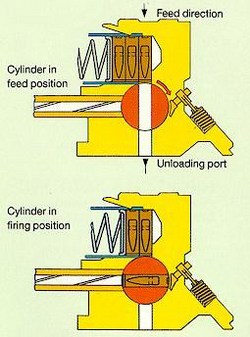

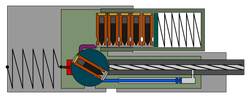

Diagram of the rotating breech system

The rifle features a unique cylinder breech/chamber system that rotates 90 degrees. The cartridges in the magazine are located above the barrel, pointing downward. Prior to each shot, a cartridge is pushed down from the magazine into the chamber, and then the chamber rotates 90 degrees to align the cartridge with the barrel. After that, the cartridge is fired and the chamber rotates back, ready for the next cartridge. Dud cartridges are ejected from a port in the bottom of the rifle, pushed out of the chamber by the next cartridge. The breech can be manually primed by the rotating handle at the side of the rifle, located beyond the pistol handle. The priming handle does not move when gun is fired.

Another interesting detail is that the barrel, rotating breech, feed module, and magazine are mounted in an internal sub-receiver that can move back and forth inside the fixed main receiver. When firing single shots, the housing moves back and forth after each shot. When firing in full-auto, the housing moves back and forth during each shot, resulting in a moderate cyclic rate of around 600 rounds per minute.

When firing in three-round bursts, the second and third cartridges are fed and fired as soon as the chamber is ready for it, and the third bullet leaves the barrel prior to the moment the housing comes to its rearward position. This results in a very high rate of fire with the three-shot bursts - around 2,000 rounds per minute. This also results in the actual recoil affecting the rifle after the last bullet in the burst is fired, which increases accuracy and makes for tighter groupings.[2]

Detailed function

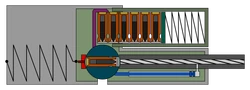

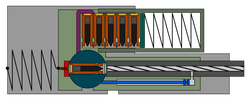

G11 function kinematic (complete cycle)

The G11 is a weapon that combines the function of a multi shot firearm with those of a transporting firearm. The aim was to create a compact core system that could slide backwards in the weapon housing. This allows the weapon to fire multiple shots before the feld recoil reaches the shooter.

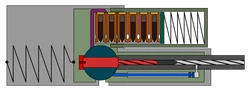

G11 Phase 1

Picture 1: The weapon is loaded, there is a cartridge in the chamber, which is cut into a rotating roller. Additional cartridges are located in the magazine above the chamber. The cartridges are stored with the bullet facing downwards.

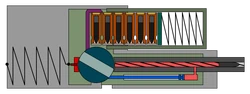

G11 Phase 2

Picture 2: The shooter pushes the trigger, whereupon the firing pin hits the primer of the cartridge. The primer flame ignites a setting charge. The purpose of this charge is to set the projectile. The pressure of the setting charge acts on the bullet's base and the breach face of the G11. The weapon's breach is part of the core system, the weapon is positively locked, the gas pressure is not able to move the breach face. The projectile, on the other hand, is propelled by the gas pressure from the main charge surrounding it. This must happen before the main charge ignites. If the main charge were to ignite prematurely, the resulting gas pressure would affect the projectile on all sides and could not accelerate it. However, since the bullet was driven into the throat of the barrel by the setting charge, it functions there as a kind of plug.

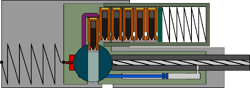

G11 Phase 3

Figure 3: Due to the heat generated by the setting charge, the main charge now also ignites, with a slight delay. The bullet, driven by the setting charge into the throat of the barrel, is now exposed to the much stronger gases of the main charge at the rear of the bullet and is driven through the barrel of the G11 by the gas pressure. Since a significant mass is accelerated, a counter reaction occurs according to Issac Newton's third law. This counter-reaction uses the powder gas column in the barrel as a fluid-mechanical body to act on the breach face of the G11. In contrast to the direct acting gas pressure, the counter reaction of the bullet movement, also known as bullet recoil, is able to drive the breach face backwards. Since the core system of the G11 is movably mounted in the weapon housing, only the core system is moved significantly backwards, with the weapon housing remaining relatively stationary. The shooter does not feel feld recoil.

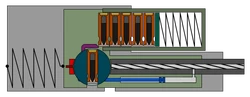

G11 Phase 4

Figure 4: The bullet passes through a gas port located at the bottom of the barrel. The highly tensioned powder gases use this opportunity to expand and pass through into a gas cylinder, where they act on all surrounding surfaces. The rear surface is the forehead of a piston, which is driven backwards. The drive piston is connected to the gear system of the G11 via a connecting rod and this ensures that the roller, where the cartridge chamber it cut into, is rotated. The drive system of the G11 is similar to a steam engine, which converts the back and forth movement of the steam piston into a rotational movement of the flywheel.

The cartridge chamber was quickly erected using a Maltese cross gear, which enables the roller to rotate suddenly within a few milliseconds. During this process, powered by local gas power, the core system of the G11 continues to move backwards. This is possible because gas forces work in a locally limited manner, which can be compared to a steam engine, which can be driven by the steam pressure even when it moves at high speed on rails.

G11 Phase 5

Figure 5: The bullet has left the barrel and the roller with cartridge chamber has been completely erected by the Maltese cross and now points its opening upwards towards the magazine. A slider that grabs the next cartridge now has the opportunity to push this new cartridge from above into the cartridge chamber in the roller. Before that, however, a second small slide is used, which moves briefly through the cartridge chamber after it has been set up. Its purpose is to unload the weapon or to remove a dud cartridge.

G11 Phase 6

Figure 6: The loading slide has completely inserted the new cartridge into the chamber in the roller. It can be noted that this fact means that the G11 is a slide loader. The cartridges are not caught by the breach face of a moving bolt, but are pushed into the chamber by a slide. Since there was no need for a recoiling bolt, the core system could be built very compactly, which made the recoiling of the core system in the weapon housing possible in the first place. The core system of the G11 still runs backwards in this phase.

G11 Phase 7

Figure 7: Due to the return spring of the gas piston, most of the movements in the system that were previously driven by the gas pressure are revised and carried out again in the opposite direction of movement. Among other things, the roller with cartridge chamber is suddenly brought back into its original vertical position by the Maltese cross gear. In this way, the new cartridge is placed in front of the barrel and is thus in the final position. A cartridge presentation occurs due to a movement of the cartridge chamber relative to the barrel. The G11 is therefore primarily a transporter and secondarily a true loader.

G11 Phase 8

Figure 8: When the core system in the weapon housing returned, the trigger group connected to the weapon housing lost control of the trigger system of the G11, which was connected to the core system. However, if this was set to burs fire before the first shot was fired, the return of the core system takes over the task of signaling the shot release. When the core system returns, an element in the stationary weapon housing touches the firing system of the G11 and a new shot is fired while the core system is returning. The process of this shot is largely identical to that of the first shot, only the return of the core system is more advanced. During the backwards movement, which is further driven by the recoil of the second shot, the ignition system is actuated again and a third shot is fired, which also follows the same pattern. This shot also drives the backwards movement of the core system further, only this time the core system hits the rear of the weapon housing. Only now is a kick felt by the shooter, as the core system, when it hits the rear wall of the weapon housing, has a large part The kinetic energy absorbed during the three shots is transferred to the housing. Before this moment, the shooter can hardly notice the recoil of the three projectiles fired. The weapon remained surprisingly stable during the first three shots, which is the actual goal of the entire design.

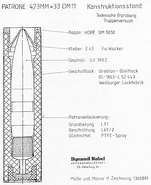

Ammunition

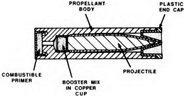

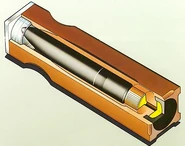

While the G11 used caseless ammunition, developed by Dynamit Nobel AG, the caliber had, in fact, evolved over time during the weapon's development. Prototypes of the weapon, along with the G11 K1, used 4.7×21mm (G11 prototypes #5 and #6), 4.3×21mm, and 4.9×20.4mm caliber rounds where the projectile sticks out the front of the propellant body. These prototypes had problems with the bullet breaking off the propellant block if handled roughly. The G11 K2 carbine used the more well-known 4.73×33mm caliber round, which had the projectile telescoped within a redesigned propellant body. The ACR variation of the weapon fired a 4.92×34mm caliber round, also of a telescoped configuration.

In the older versions of the ammunition, the solid propellant body was made of compressed NC gunpowder, until they had switched to HITP (high-ignition temperature propellant) by the time that the 13th prototype was developed. There were also variations of the rounds designed to combat the G11's cook off problems, from aluminum foil being wrapped around the propellant body, to silver-coated propellant bodies.

During the Advanced Combat Rifle program, U.S. Army personal believed that combining the the heat sink technology of AAI's earlier AIWS caseless rifle prototypes with the high-ignition temperature propellant of the G11's ammunition could have resulted in a weapon superior to both and far less complex, but due to protection under license agreements with both Heckler & Koch and Dynamit Nobel, the details on the G11's propellant could not be divulged. Ironically the U.S. Army itself could not even test its theory of combining the two technologies together in-house to create a new weapon due to a lack of funding.

Trivia

- The G11 had only ever made one appearance in a motion picture media, in the 1993 science fiction film Demolition Man, where it is depicted as a futuristic "Magnetic Accelerator". The G11 was still undergoing development at the time of the film's production, so the film's G11 was a mockup cast from a real G11 prototype loaned to the production.

Gallery

See also

- Competing ACR designs

- Steyr ACR

- Colt ACR

- AAI ACR

- ARES-Olin AIWS

- McDonnell Douglas AIWS

- G11 caseless round

- Caseless ammunition

- Telescoped ammunition

- Advanced Combat Rifle program

Notes

- ↑ 1991-1992 represents the period when the G11 was adopted by the Bundeswehr. However, almost no units were actually produced in this period.

References

- "Калашников" 4_2007 "Не перевелись еще "специалисты на Руси..."

- Modern Firearms - Heckler und Koch G11 (Germany)

- WHQ forum topic discussing the G11 (German)

- Docdroid PDF Advanced Combat Rifle program

- RCT66 Tumblr datasheet

| |||||||||||||||||||||||||||||